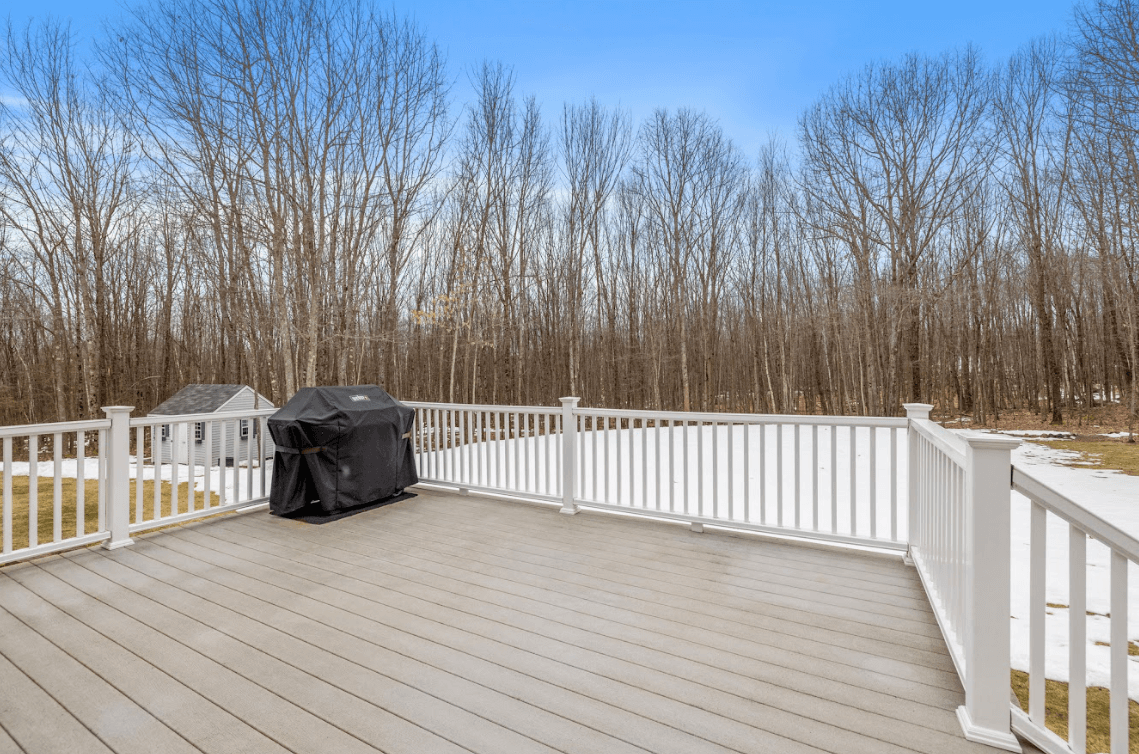

Winter weather brings unique challenges, especially for decks exposed to freezing temperatures, snow, and ice. However, selecting the right materials ensures your deck remains durable and safe through every season.

From resisting moisture damage to preventing warping, certain materials are better suited to withstand winter. Prince William Home Improvement, a deck builder in Virginia and Maryland, offers expert solutions for building winter-resistant decks, helping homeowners enjoy beautiful, low-maintenance outdoor living spaces year-round—even in colder months.

What Makes a Deck Winter-Resistant?

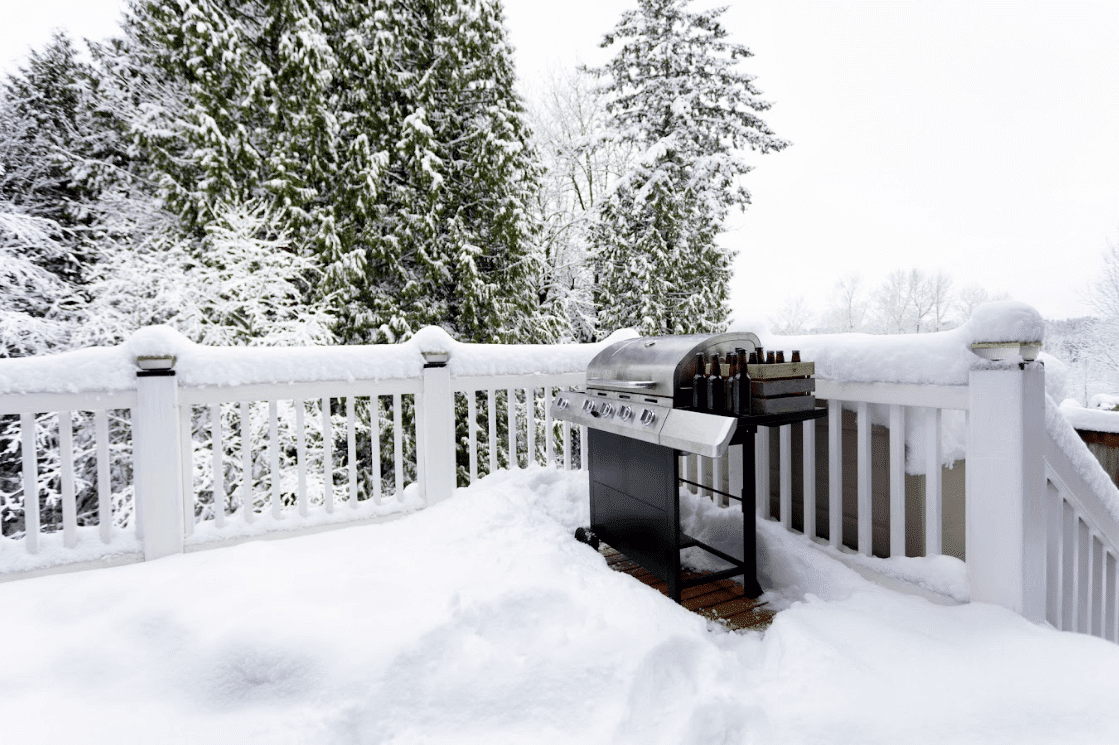

Building a deck in winter demands materials designed to handle the season’s toughest conditions. Cold weather, snow, and ice can take a toll on outdoor surfaces, causing cracks, warping, and even mold growth.

Understanding the challenges decks face in winter helps homeowners choose the right decking materials to ensure long-term durability. Planning your deck project with winter-ready materials protects your investment from harsh conditions.

- Common Winter Issues: Moisture trapped under snow can freeze, expand, and cause deck boards to warp or split. Repeated freezing and thawing cycles often result in surface cracks. Mold and mildew are common when decks retain moisture, creating a slippery and unsafe surface.

- Key Properties to Look For: You want water resistance materials to minimize moisture absorption and prevent swelling or warping. Freeze/thaw durability of the materials that resist cracking during temperature fluctuations extends the deck’s lifespan. Non-slip surfaces to help prevent accidents, even when ice or snow is present. Low-maintenance properties that reduce the need for frequent repairs or sealing throughout the season.

Trex Composite Decking: Engineered to Handle Winter

Trex composite decking is one of the top choices for winter-resistant decks, thanks to its unique composition and durability. Engineered from recycled wood fibers and plastic, it provides excellent resistance to mold, warping, and cracking during freezing conditions.

- Composition & Durability: Trex decking uses non-porous recycled materials, preventing water absorption and swelling. It resists mold growth, splitting, and cracking even in freezing temperatures.

- Winter Benefits: Trex’s non-slip surface minimizes ice buildup, making it safer to walk on during snowy weather. It won’t warp or split under harsh freeze/thaw cycles, keeping it structurally sound.

- Why Homeowners Prefer Trex: These composite decking materials require less upkeep than wood while maintaining a natural, wood-like appearance. Its long-lasting color and texture make it a popular option for winter-resistant decks.

Pressure-Treated Wood: Traditional but Resilient

For homeowners who prefer the natural charm of wood decks, pressure-treated wood remains a popular option, offering some durability and resilience with the right care. It undergoes chemical treatment to resist rot, mold, and insect damage, making it suitable for outdoor conditions. Though wooden decks can endure winter weather, they require more maintenance to stay in good shape.

- Winter Durability: Pressure-treated wood is infused with preservatives that help it withstand freezing and thawing cycles. The treatment prevents mold and rot, ensuring the deck remains safe even in wet, cold weather.

- Potential Challenges: Wood is more susceptible to warping and cracking over time, especially if left unsealed. It needs regular maintenance to maintain its integrity through tough winters.

- Why Some Homeowners Choose Wood: Pressure-treated wood offers a classic, natural look at a lower upfront cost. It’s a practical option for those who prefer traditional aesthetics over composites. Choosing the right wood decking materials ensures your deck stays sturdy through winter’s freeze-thaw cycles.

Comparing Trex Composite and Pressure-Treated Wood for Winter Use

When choosing the best material for a winter-resistant deck, both Trex composite decking and pressure-treated wood offer distinct advantages. However, they differ in performance, upkeep, and long-term costs, which can impact your decision.

- Weather Performance: Trex composite decks require minimal maintenance, unlike wood, reducing the risks of warping and mold. Pressure-treated wood can endure cold weather but may require sealing to prevent water absorption.

- Maintenance Demands: Composite decking is easier to maintain, with no need for sanding, sealing, or staining. Pressure-treated wood needs regular sealing and occasional sanding to protect against winter damage.

- Budget Considerations: Composite decking involves a higher upfront investment but lowers maintenance costs over time. Wood decking has a more affordable initial cost but requires more frequent maintenance, which can add up.

- Appearance & Feel: Trex composite decking offers a wood-like appearance with color options that remain vibrant over the years. Pressure-treated wood provides an authentic, natural look but may fade or crack without proper care.

Winter Deck Maintenance Strategies

Proper maintenance ensures your winter-resistant deck stays safe and looks great throughout the season. Whether you choose composite, wood, or alternative materials, a few simple practices can help you avoid damage and extend the deck’s lifespan. Use a deck cleaner before winter to remove dirt and debris that could trap moisture under snow.

- Efficient Snow Removal: Use plastic shovels or brooms to remove snow without scratching or damaging deck surfaces. Clear snow regularly to prevent buildup that could lead to moisture problems.

- Ice Prevention: Apply calcium chloride-based ice melts, which are safe for composite and wood surfaces. Avoid rock salt, as it can harm finishes and cause corrosion over time.

- Routine Inspections: Check for cracks, swelling, or warping after storms or heavy snowfall. Address minor issues quickly to prevent them from worsening during repeated freeze/thaw cycles.

Build a Winter-Resistant Deck That Lasts with Prince William Home Improvement

A winter-resistant deck protects your investment, ensuring it stays safe, beautiful, and functional during every season. Whether you prefer the low upkeep of Trex composite decks or the timeless appeal of wooden decks, selecting the right materials is key to lasting durability. Prince William Home Improvement, a Maryland and Virginia deck builder, specializes in building outdoor living spaces that stand up to winter’s toughest conditions.

Ready to start your decking project? Contact us today to schedule your consultation. Let us help you design and construct the perfect winter-ready deck so you can enjoy it year-round—no matter the weather!